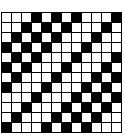

So lately I’ve been on a kick knitting little pouches in 2 colours. The pouches are usually 64 stitches in the round, knitted with 5 needles, so each needle (except the active one) has 16 stitches on it. They’re small enough that they knit up quickly and I can play with patterns. The last few pouches, I’ve been playing with interlaced patterns. These pouches are all knitted with 2/18 merino wool, on size 0 needles and are large enough to hold some coins, or a medallion, or some such.

Based on medieval (but much larger) pouches, they’re knitted top down, with holes near the top edge for the eventual drawstring, and finished on the bottom with a 3 needle bindoff. Basically, transfer the stitches onto 2 needles in parallel, and then on each stitch go through a stitch from each needle together. This sounds more awkward than it should.

While I think about it, the holes are made by knitting together, on each of the four needles, stitches 3&4, 5&6, 11&12, and 13&14. Then on the next row after the 3rd and 9th stitches, add 2 stitches back in using yarnovers.

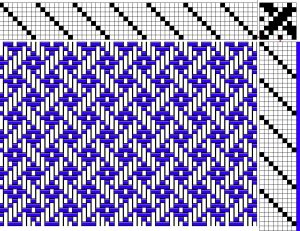

First Attempt

Second Attempt

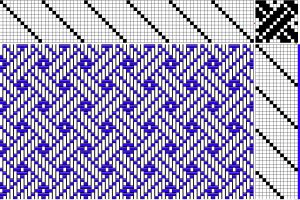

Doublesided

Still Doublesided

So the red and grey was my first attempt at interlacing. While technically interlaced, the diagonal bars were two close together so you can’t really see what’s going on.

After that I started playing with the magenta, which worked better. What you can’t see in these pouches of course is the crossing point at one edge where everything looks just a little wonky because you’re knitting in the round.

Which brought me to the current attempt in green and vanilla, where the two sides of the pouch are mirror images. That way the pattern extends exactly to the edge, but no further.

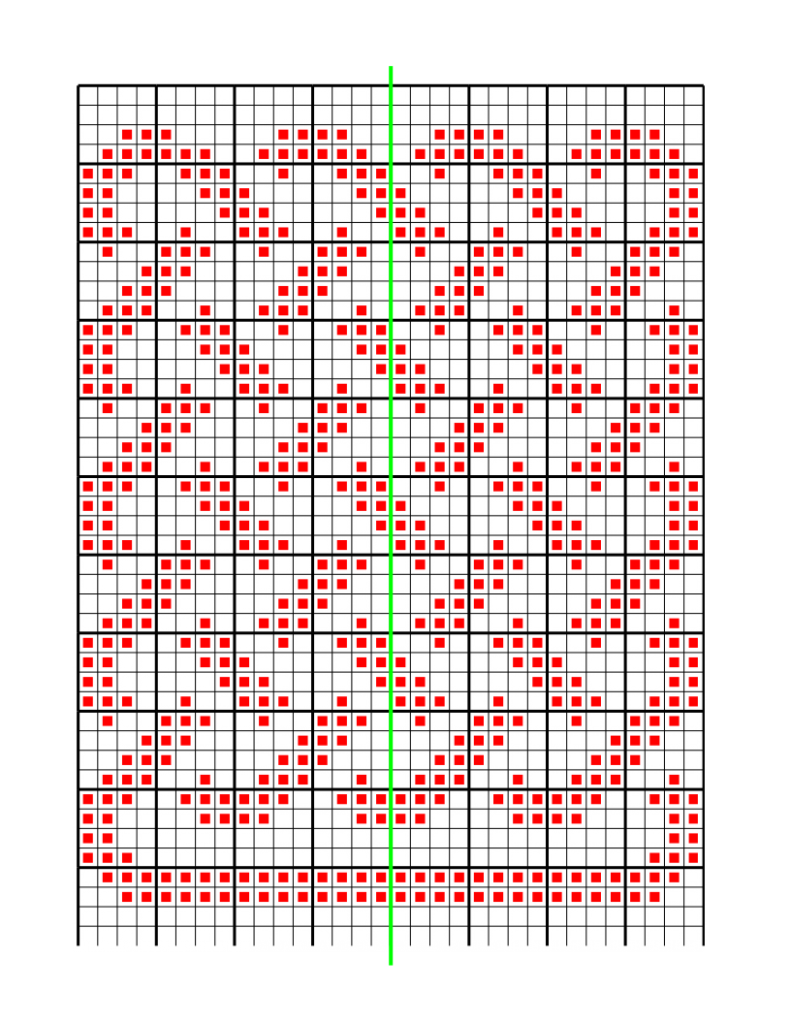

The pattern here is for one side of the pouch – 2 needles wide. The light green line marks the boundary between the two needles.

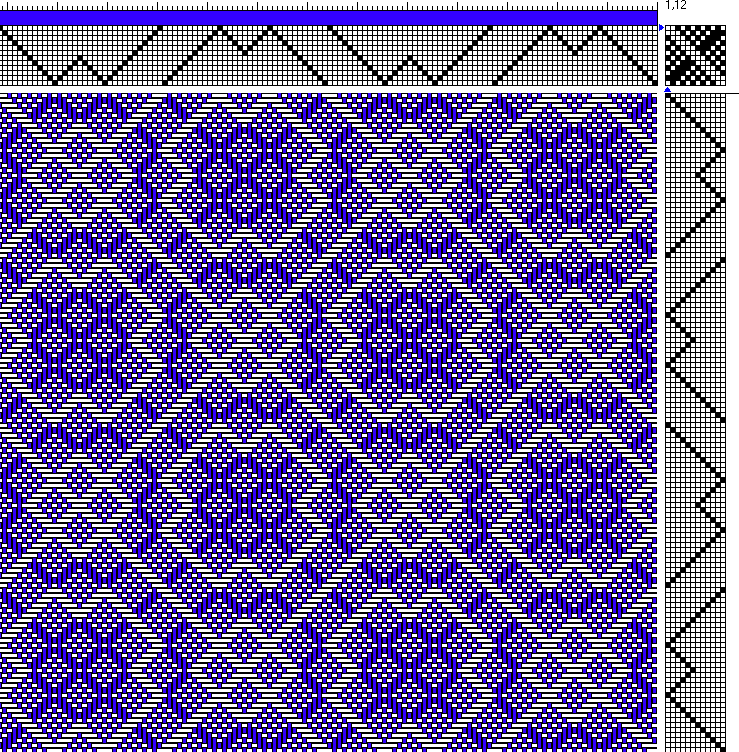

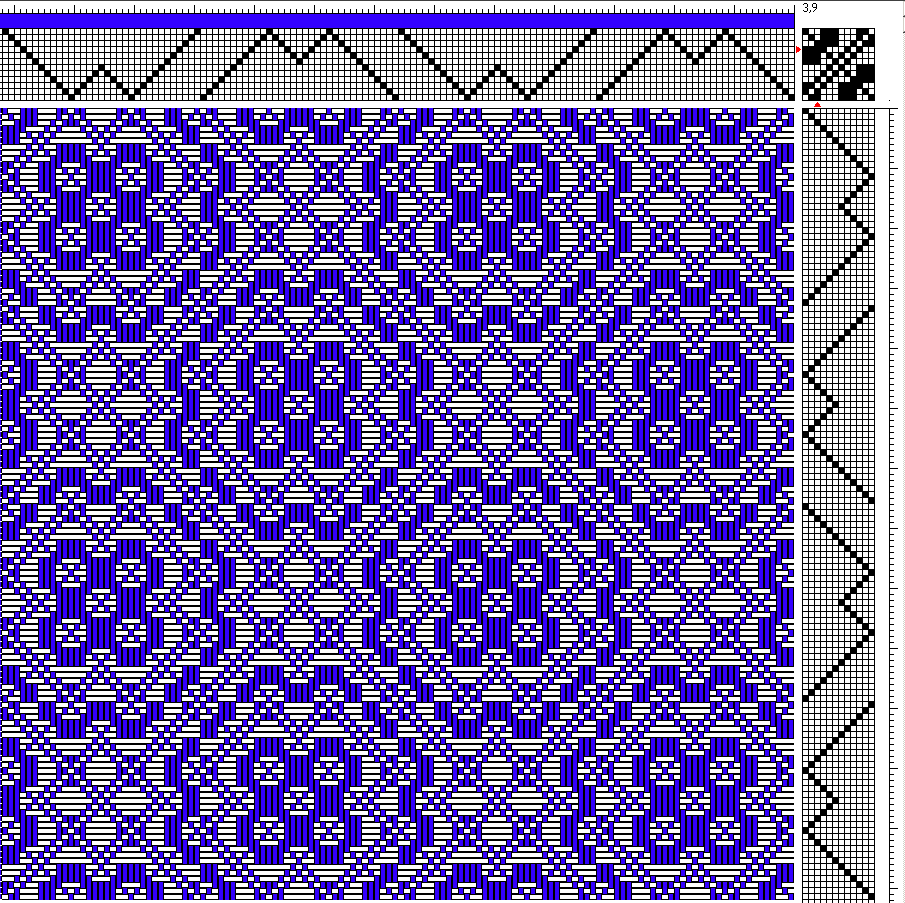

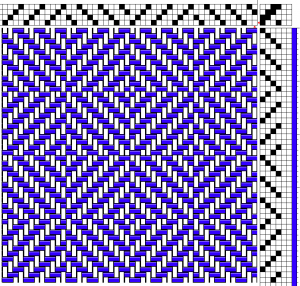

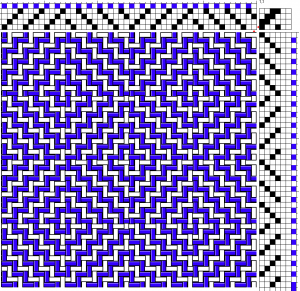

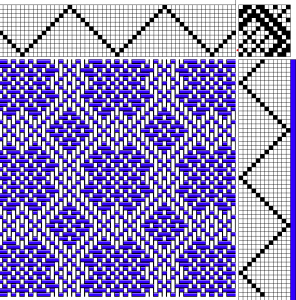

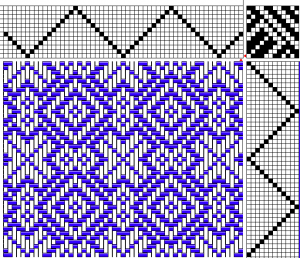

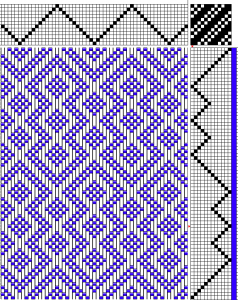

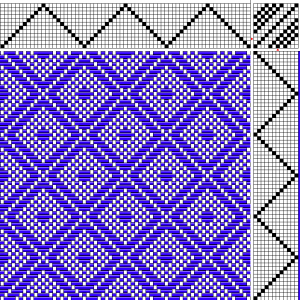

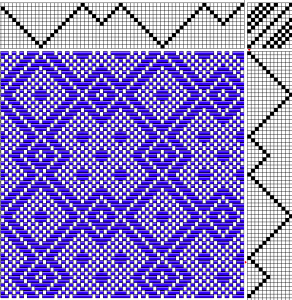

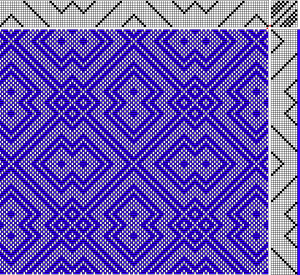

So while I’ve been quiet here, I’ve finally been weaving on the 12 harness Leclerc. The design of the loom, it turns out, has some major, and annoying, flaws. Worst is the way I can’t adjust the harnesses so that the string, traveling from back to front beam, lies flat. Since the heddle eyes are below this level, the strings all come off the backbeam, slant down, go through the heddle, and then slant back up. There’s enough distance between the first and twelfth harness that when all the harnesses are down there’s a visible deformation … And there’s tension issues, too. Between that, and getting the loom warped, and then trying to fix it, it took a little longer to get weaving than I had hoped.

So while I’ve been quiet here, I’ve finally been weaving on the 12 harness Leclerc. The design of the loom, it turns out, has some major, and annoying, flaws. Worst is the way I can’t adjust the harnesses so that the string, traveling from back to front beam, lies flat. Since the heddle eyes are below this level, the strings all come off the backbeam, slant down, go through the heddle, and then slant back up. There’s enough distance between the first and twelfth harness that when all the harnesses are down there’s a visible deformation … And there’s tension issues, too. Between that, and getting the loom warped, and then trying to fix it, it took a little longer to get weaving than I had hoped.

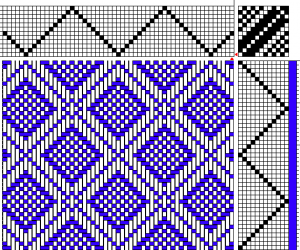

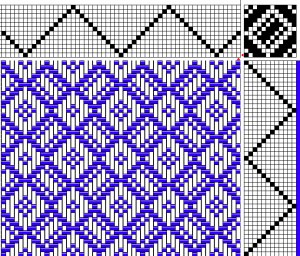

What we’ve done here is add some partial reflections, where the threading/treadling change direction after only 6 strings instead of 12. The basic bloc is still the same size, But a full repeat of the pattern is now 32 threads wide and high.

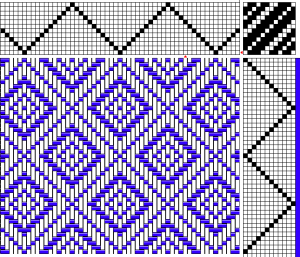

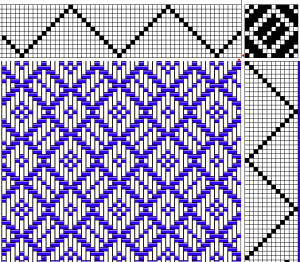

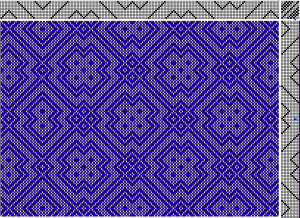

What we’ve done here is add some partial reflections, where the threading/treadling change direction after only 6 strings instead of 12. The basic bloc is still the same size, But a full repeat of the pattern is now 32 threads wide and high. Of course the next logical experiment is to add translations. Translations occur when you keep going in the same diagonal direction for more than 12 picks, which you see here in the parallel lines in the pattern. And the pattern is now 56 threads wide and tall. (And yes, on the left side I forgot a reflection in the threading, so there’s an unevenness there. Oops)

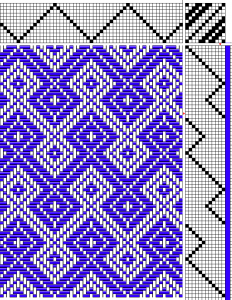

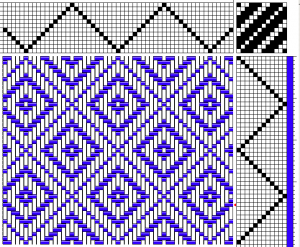

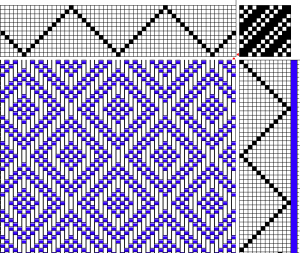

Of course the next logical experiment is to add translations. Translations occur when you keep going in the same diagonal direction for more than 12 picks, which you see here in the parallel lines in the pattern. And the pattern is now 56 threads wide and tall. (And yes, on the left side I forgot a reflection in the threading, so there’s an unevenness there. Oops) And then there’s this last Variation, where translations have been utilized to make the individual building blocks much bigger than they really are.

And then there’s this last Variation, where translations have been utilized to make the individual building blocks much bigger than they really are.