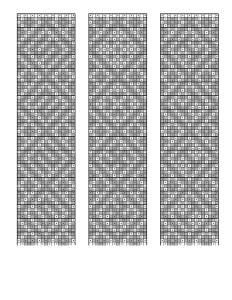

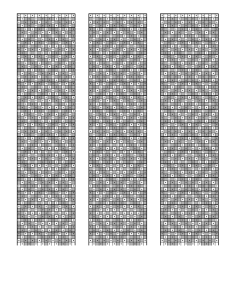

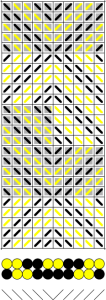

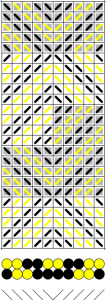

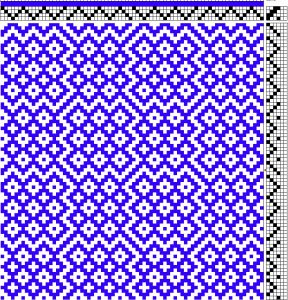

An M-W threading is named for the threading through the heddles, which looks like repeating Ms and Ws on the form. The pattern I was playing with is a modified M W, where each M and W has three high (or low) points. I’ve warped up umpty yards (he warp was measured for a sampler, so … I forget?), and enough ends for 8 repeats, warped alternating 2 olive repeats and 1 tan repeat. The goal is to vary the weft in multiple projects. Unfortunately I forgot to photograph the first two stretches, where the weft was respectively burgundy, and white, so that will have to wait until it comes off the loom.

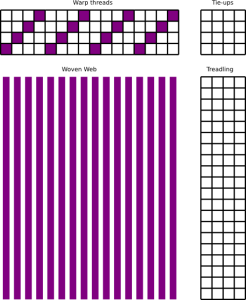

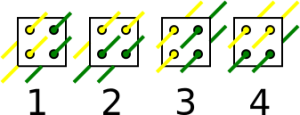

Once the threading through the headings was decided, and going with a simple twill tie up, the next step is to decide the treadling. (I.e. in which order do the four harnesses get raises, or in what order are the treadles pressed?) This first version looks more complicated than it actually is, mostly because I didn’t pick the best starting point.

In a simple twill weave, the treadling is 1-2-3-4 and repeat. A twill diamond pattern, on the other hand, will treadle 1-2-3-4 followed by 3-2-1-4 for a 8 line pattern. In my way of thinking, that would be a 4 row diamond. In the pattern above, we have a 6-row diamond twill: 4-1-2-3-4-1 followed by 4-3-2-1-4-3. This looks confusing at first, but by thinking of it as a six row diamond, I can reuse the muscle memory from previous projects.

On the other hand, the pattern looked very horizontal; it’s hard to make striped with just diamonds, but by golly I managed. Also; I had woven two 19 or so inch lengths, and was bored.

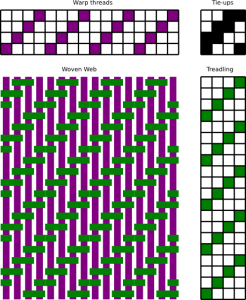

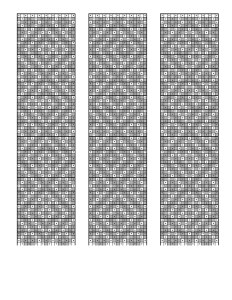

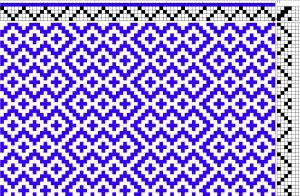

Time to start playing with alternating treadlings. This is where I once again thank my husband for the gift of a lovely piece of software (Fiberworks Bronze) which allows me to both typeset and change patterns up quickly and easily. I’m still far from adept at pattern design, but the software lets me experiment with different treadlings really, really quickly.

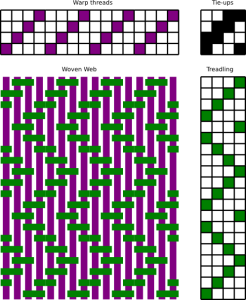

My first idea was to treadly the same way as the heddles were threaded in extended Ms and Ws. As it turned out, that gave a slightly unbalanced pattern and I experimented a little more, resulting in this pattern.

Oddly enough, I didn’t realize that this is still an extended MW treadling, except that if the extended M’s are treadled just as they’re threaded, the extended W’s are shifted one over, resulting in a 3-2-1-4-1-2-3 effect. There’s exactly 1 extra treadling (using 4) between the M’s and W’s which makes this pattern again really easy to memorize. Plus there’s lots of visual cues in the weaving, of course.

So what does the fabric look like? The weft is a lighter brown than the tan warp, keeping the pattern visible (albeit more subtle) on the tan stripes. As well, the edges are the best I’ve had on this yardage yet; there’sa floating selvage on both sides, but here I’m always treadling an even treadle when entering from the right, where in the previous bitsy bobs I always entered from the right on an odd treadle. Funny the different that can make.

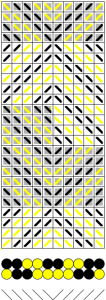

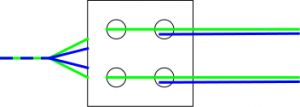

In the horizontal position, the top two threads are both green. In this position, I will weave another green row regardless of whether I turn forwards or backwards.

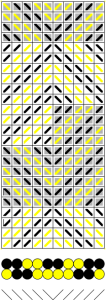

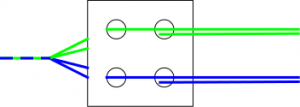

In the horizontal position, the top two threads are both green. In this position, I will weave another green row regardless of whether I turn forwards or backwards.